Last Updated on April 22, 2025

It’s completely normal to feel anxious when your vehicle’s check engine light (CEL) suddenly appears on the dashboard. You might be cruising down the road, enjoying the ride, and suddenly, the Malfunction Indicator Lamp (MIL) blinks. This flashing light is your car’s way of saying, “Something’s wrong.” If your scanner pulls up the P0017 Code, you’re likely facing a serious camshaft-to-crankshaft misalignment issue.

It’s completely normal to feel anxious when your vehicle’s check engine light (CEL) suddenly appears on the dashboard. You might be cruising down the road, enjoying the ride, and suddenly, the Malfunction Indicator Lamp (MIL) blinks. This flashing light is your car’s way of saying, “Something’s wrong.” If your scanner pulls up the P0017 Code, you’re likely facing a serious camshaft-to-crankshaft misalignment issue.

This could lead to poor engine performance, increased emissions, or even long-term engine damage if not addressed promptly. Thankfully, this article breaks down everything you need to know—from symptoms to repair strategies—to help you fix the problem and protect your engine.

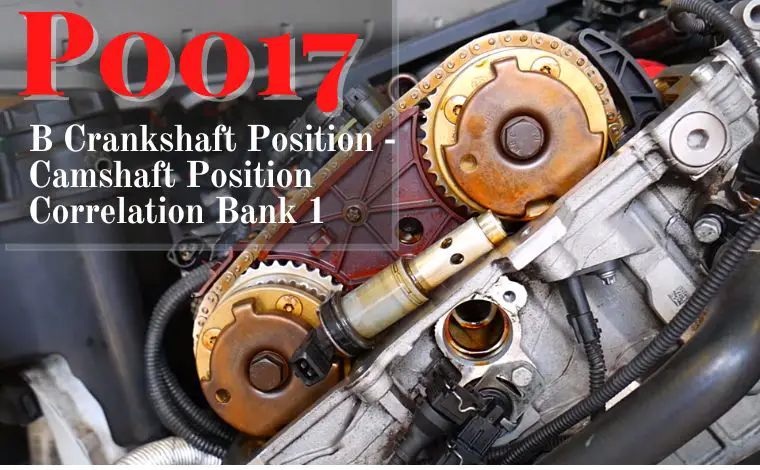

What Does Code P0017 Mean?

P0017 is a generic powertrain code that refers to “Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor B).” In simple terms, the PCM (Powertrain Control Module) is detecting a timing misalignment between the crankshaft and the exhaust camshaft on Bank 1 (the side of the engine containing cylinder 1).

For an internal combustion engine to operate smoothly, camshaft and crankshaft timing must be perfectly synchronized. If this synchronization is off, combustion timing is affected, leading to misfires, loss of power, and potential internal damage.

- “Bank 1” refers to the side of the engine with the number 1 cylinder.

- “Sensor B” usually refers to the exhaust camshaft position sensor (as opposed to Sensor A, which typically monitors the intake).

Common Symptoms of Code P0017

When P0017 appears, your vehicle may display one or several of the following warning signs:

- Check Engine Light Illuminates or Flashes

- This is often the first and most obvious sign.

- Hard Starts or No Start

- Misaligned timing can make it difficult to start the engine.

- Rough Idling or Stalling

- The engine may idle unevenly or stall at low speeds or while stopped.

- Decreased Fuel Efficiency

- Inaccurate timing affects combustion, leading to increased fuel use.

- Reduced Engine Power

- The car may feel sluggish, especially during acceleration.

- Knocking or Rattling Sounds

- A stretched timing chain or damaged gear could cause abnormal noises.

- Inconsistent Engine RPMs

- You may notice random RPM surges while idling or driving.

- Increased Emissions

- A misaligned cam/crankshaft can lead to poor combustion and excess exhaust.

Causes of P0017 Error Code

Several mechanical or electronic problems can lead to the P0017 code. These include:

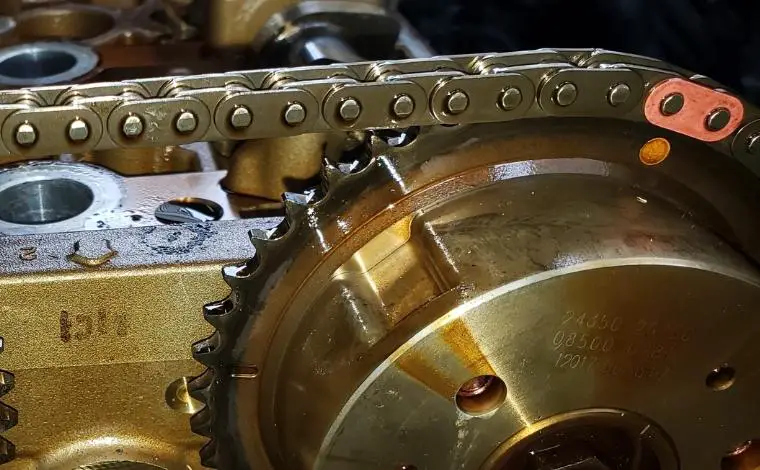

- Stretched or Worn Timing Chain or Belt

- Over time, the timing components wear and lose tension.

- Faulty Camshaft or Crankshaft Position Sensor

- A bad sensor or damaged wiring can send incorrect signals to the PCM.

- Worn Timing Gear or Sprockets

- The gears that connect the timing belt/chain can degrade.

- Oil Flow Issues in VVT System

- Dirty or low-viscosity oil can affect the cam phaser and actuator performance.

- Damaged Tone Ring

- A missing or damaged reluctor ring (tone ring) can cause signal errors.

- Faulty VVT Solenoid or OCV (Oil Control Valve)

- Failure of this part affects valve timing adjustment.

- Incorrect Oil Viscosity

- Always use the manufacturer-recommended oil grade for your engine.

How to Diagnose Code P0017

To effectively troubleshoot and resolve code P0017, follow this step-by-step diagnostic process:

✅ Step 1: Connect OBD-II Scanner

- Use an advanced OBD2 scanner to pull all related codes.

- Check for multiple codes that may help narrow down the root cause.

- Note the freeze frame data to see when the code was triggered.

✅ Step 2: Visually Inspect Timing Components

- Open the timing cover and check for belt slack, chain looseness, or gear wear.

- Look for missing teeth or cracks in timing components.

✅ Step 3: Check Sensor Signals

- Test the camshaft and crankshaft position sensors with a multimeter.

- Compare actual values with OEM specifications.

✅ Step 4: Examine Engine Oil

- Check oil quality, level, and viscosity.

- Old, dirty oil can cause VVT solenoid blockages.

✅ Step 5: Inspect Wiring and Connectors

- Look for corroded, frayed, or loose connectors.

- Sensors rely on clean, tight connections for accurate data.

✅ Step 6: Inspect VVT Solenoids and OCV

- Remove and clean the VVT solenoid or OCV.

- Replace if clogged or not functioning properly.

🛠️ How to Fix Code P0017 (Fully Detailed)

Fixing code P0017 involves replacing or adjusting components related to engine timing and sensor communication. Depending on the diagnosed root cause, here are the most relevant repair options:

✅ 1. Replace a Stretched Timing Chain or Worn Timing Belt

Over time, the timing chain can stretch, and the belt may wear or slip, throwing off timing alignment.

- Replace the chain or belt if it shows signs of slack, damage, or wear.

- Don’t forget to replace the timing tensioners, guides, and sprockets for complete reliability.

- Ensure timing marks are perfectly aligned during reassembly.

This is often a labor-intensive job, requiring several hours and special tools.

✅ 2. Replace Faulty Camshaft or Crankshaft Position Sensors

If the sensors are out of specification:

- Remove the old sensor and replace it with an OEM-quality replacement.

- Clear any debris or rust around the mounting area.

- Ensure proper torque when reinstalling.

Even a minor sensor fault can confuse the PCM, causing incorrect timing adjustments.

✅ 3. Replace or Clean the Oil Control Valve (OCV)

If the OCV or VVT solenoid is clogged:

- Remove and clean with brake cleaner or engine degreaser.

- Test the actuation by applying battery voltage.

- If it fails to respond, replace the entire unit.

An OCV that fails to open/close properly will disrupt camshaft advance/retard functions.

✅ 4. Adjust or Replace the Tone Ring

If the tone ring is misaligned or damaged:

- Remove the crankshaft pulley or cam gear (depending on location).

- Realign or replace the tone ring.

- Re-check sensor readings post-replacement.

This is especially important for reluctor-based sensors, which rely on precision.

✅ 5. Repair Wiring or Connector Faults

If electrical communication is compromised:

- Trace wiring from the PCM to the camshaft/crankshaft sensors.

- Repair or replace burned, frayed, or pinched wires.

- Use dielectric grease on connectors to improve signal and protect from moisture.

Electrical issues are often intermittent, so patience and precision are key.

✅ 6. Update or Reprogram the PCM (if necessary)

Some manufacturers release software updates to address sensor correlation issues.

- Check Technical Service Bulletins (TSBs) related to your vehicle model and year.

- Visit a dealership or use OEM diagnostic software to update the PCM.

✅ 7. Change Engine Oil and Filter

Always complete the repair by performing a full oil and filter change, especially if:

- You found sludge or debris in the OCV.

- The oil was old or the wrong viscosity.

- The engine hasn’t been serviced regularly.

Using the correct oil will help the VVT system function properly going forward.

⚠️ Bonus Tip:

Do not forget to reset the PCM after any significant timing-related repair. Failure to do so may keep the check engine light active, even if the issue is resolved.

Step-by-Step Troubleshooting Tips for P0017

Troubleshooting the P0017 error code requires a structured and methodical approach. Below are detailed steps to help you identify and resolve the root cause:

🔍 1. Perform a Thorough Visual Inspection

Start with a basic visual check under the hood:

- Inspect the camshaft and crankshaft sensors and their connectors.

- Look for loose, corroded, or damaged wiring harnesses.

- Examine the timing cover area for oil leaks that might affect sensor accuracy.

- Check for sludge buildup around the VVT solenoid or OCV (Oil Control Valve) housing.

A visual inspection may reveal issues such as broken clips, dirty connectors, or sensor damage, saving you time before moving to deeper diagnostics.

⚡ 2. Test Camshaft and Crankshaft Position Sensors

Using a digital multimeter or oscilloscope, check the output of both sensors:

- Disconnect the sensor harness and test for resistance according to OEM specifications.

- If using an oscilloscope, watch for waveform patterns during engine cranking.

- Replace the sensor if readings are out of spec or if the waveform is erratic or absent.

Tip: A bad sensor may not trigger a separate DTC but can still lead to a P0017 code due to miscommunication with the PCM.

🛠️ 3. Inspect the Timing Chain or Belt System

Timing issues are the most common cause of a P0017 code. Remove the necessary covers to:

- Check for a stretched timing chain, worn guides, or missing teeth on a timing belt.

- Rotate the crankshaft manually to observe if the cam and crank rotate synchronously.

- Compare the physical timing marks on the camshaft and crankshaft pulleys.

If the timing is even slightly off, it can cause incorrect valve operation, resulting in this fault code.

💧 4. Verify Engine Oil Condition and Flow

Check both the quality and level of engine oil:

- Use a dipstick to check if the oil level is within the safe range.

- If oil appears dirty, thick, or sludgy, change it immediately.

- Make sure you use the manufacturer-recommended oil viscosity.

Low oil pressure or dirty oil can disrupt VVT system performance, especially in engines with hydraulic cam phasers.

🔩 5. Inspect and Test the Oil Control Valve (OCV)

The OCV, also called the VVT solenoid, controls oil flow to the cam phaser. Here’s how to check it:

- Remove the valve and inspect for clogs or sludge.

- Apply battery voltage (if applicable) and ensure the plunger actuates.

- If the valve is stuck, weak, or inoperable, replace it.

A restricted or faulty OCV can misadjust camshaft timing and trigger the P0017 code.

🧰 6. Check the Tone Ring (Reluctor Ring)

This component, mounted on the camshaft or crankshaft, helps the sensor read rotational position.

- Ensure the tone ring isn’t cracked, warped, or misaligned.

- Check that it hasn’t slipped out of position due to loose bolts or faulty mounting.

- If it’s damaged, replace it immediately.

A bad tone ring sends incorrect timing signals, causing sensor confusion.

🚗 7. Clear Codes and Perform a Test Drive

After addressing any of the above issues:

- Clear the DTC using an OBD-II scanner.

- Perform a test drive under normal driving conditions.

- Re-scan the vehicle to see if the P0017 code reappears.

If the problem persists, proceed to advanced diagnostics or consider replacing multiple timing components.

Estimated Cost to Fix P0017

Costs can vary by region, vehicle type, and part availability. Below is a general cost breakdown:

| Repair or Replacement Item | Estimated Cost |

|---|---|

| Timing Chain or Belt | $300 – $3000 |

| Camshaft/Crankshaft Position Sensor | $150 – $450 |

| VVT Solenoid or OCV | $200 – $300 |

| Crankshaft/Camshaft Tone Ring | $100 – $600 |

| Wiring/Connector Repair | $100 – $500 |

| Professional Diagnosis | $80 – $150 |

Where Is the Camshaft Sensor Located?

The camshaft sensor is generally found:

- Near the top of the engine, often attached to the valve cover.

- In front of the engine block or near the timing components.

- On some models, especially inline engines, near the first cylinder head.

Always consult your vehicle’s repair manual for accurate location details.

Related OBD-II Trouble Codes

If you’re dealing with P0017, you might also see:

- P0012 denotes that “A” Camshaft Position – Timing Over-Retarded (Bank 1)

- P0013 stands for “B” Camshaft Position – Actuator Circuit (Bank 1)

- Trouble code P0014 notifies that “B” Camshaft Position – Timing Over-Advanced or System Performance (Bank 1)

- P0015 means that “B” Camshaft Position -Timing Over-Retarded (Bank 1)

- P0016 suggests that Crankshaft Position – Camshaft Position Correlation (Bank 1 Sensor A)

- OBD code P0018 stands for Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor A)

- P0019 DTC elaboration is Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor )

- P0020 stands for “A” Camshaft Position Actuator Circuit (Bank 2)

Each of these relates to camshaft timing and VVT system health.

Frequently Asked Questions (FAQ)

Can I drive with P0017?

Technically yes, but it’s not recommended. Continued driving can lead to severe engine damage and increased repair costs.

Can a bad oil filter cause P0017?

Yes. A clogged or improper oil filter can restrict oil flow to the VVT system, causing timing issues.

Is P0017 a timing chain problem?

Often yes, especially in high-mileage vehicles. A stretched or worn timing chain is a common root cause.

Can low oil level trigger P0017?

Absolutely. Low oil affects hydraulic timing actuators and can throw off timing accuracy.

Conclusion

P0017 is more than just a nuisance code—it’s a warning of a serious engine synchronization problem that needs immediate attention. Whether it’s a stretched timing chain, sensor failure, or improper oil viscosity, the issue must be resolved to avoid long-term damage.

If you’re a DIYer, this article offers a detailed roadmap for resolving the problem yourself. However, if you’re unsure or lack the right tools, consult a professional mechanic for a proper diagnosis and repair.

Address the code early, save yourself from high repair bills, and keep your engine running smoothly and efficiently.

Kevin Nicholas is an automotive technician who is a genius at software and hardware-related issues. He manually tested more than a hundred OBD scanners and gave his honest opinion on whether the device was worth the money or not. His in-depth OBD review articles help people choose the right product, whether it is a European, American, or Asian vehicle. He completed his Automotive Specialized Training Course at Universal Technical Institute and has more than 15 years of experience in the field.