What Does P0008 Mean?

The DTC code P0008 stands for the “Engine Position System Performance Bank-1.” This is a common type of problem that is associated with the mechanical timing between the crankshaft and bank one camshaft. The ECM sneaks out the irregularities in the crankshaft and camshaft sensor. The sensors detect that the ECM controls ignition and fuel timing in case of various loads, and this code is most common in the Suzuki, GM, Cadillac, Buick, Holden, Chevrolet, and GMC brand cars.

What Are the Possible Symptoms Of the P0008 Code?

The OBD-II code P0008 denotes improper timing in the engine positioning. There are several symptoms that the error code P0008 may produce, such as,

- The vehicle may show up rough, accelerate, and run rigidly.

- The fuel economy is decreased from the actual value.

- The timing chain may produce an irresistible rattling noise

- The MIL or CEL may start to illuminate

- The engine may be stopped all of a sudden

What Are The Reasons For P0008?

The DTC code may produce from several issues generated by the components of the crankshaft and camshaft. There are tons of causes that the MIL starts to blink and show the P0008 code; they are,

- The timing chain must be stretched or may get out of sync. The wiring must produce some sort of abnormality, or there might be discontinuation in the connection of the wiring.

- Malfunctioning may happen in the camshaft or crankshaft sensors. The sensors are kind of sneaky, and they figure out every deformity in the system. The components which command gears, guides, and chains may get out of order.

- A disguised error may occur in the ECM, or it may be worn out. There might also be a faulty variable valve timing solenoid or variable valve timing actuator present in the system. Sometimes the indicator may illuminate the low engine oil level.

How Severe Is the P0008 Code?

The P0008 code actually denotes the fault in the powertrain control module. It may create severe injury to the engine’s power performance. The intensity to cause harm to the engine is recorded much higher when the P0008 code appears. This code may decline the fuel economy of the engine. The gas emission from the exit pipe may be hampered as black and white fumes appear in the process. Some of the gas or fumes got arrested within the system, which caused severe illness to the vehicle. The engine’s power may be reduced, and it may remain idle for some time. If you do not address the problem initially, it may create several engine fatalities in the future.

How To Diagnose And Repair Code P0008?

Diagnosis of the code P0008 is not that simple, as the problem is related to the engine’s powertrain control module. You may take help from the manufacturer-specific service manual. Everything is elaborated with necessary drawings, and you can easily realize where the problem has occurred.

Diagnosis method

The P0008 fault code may be diagnosed starting by examining the crank and cam sensor pattern. The professionals use an oscilloscope to scrutinize those. The crankshaft was diagnosed when the engine was on at the very first. It requires a full 720-degree capture of the crankshaft dividing it into two equal portions of 360-degree capture rotation. There is a library available to the automakers from which they can realize the pattern of the crankshaft rotation; if this equates to the standard graph, then there is no fault between the crankshaft and camshaft.

But it is pretty much obvious that the diagnosis process may initiate by connecting an advanced scanning tool to the car. The mechanic checks the actual faults in the OBD-II scanning tool. They may have encountered more than one error code which will be solved simultaneously or one by one.

Repairing Strategy

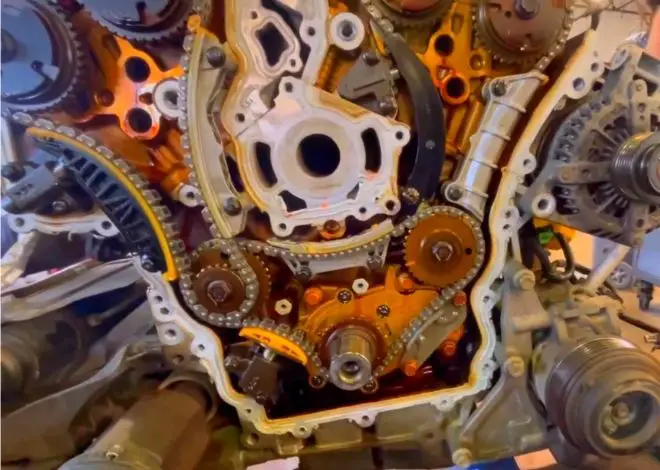

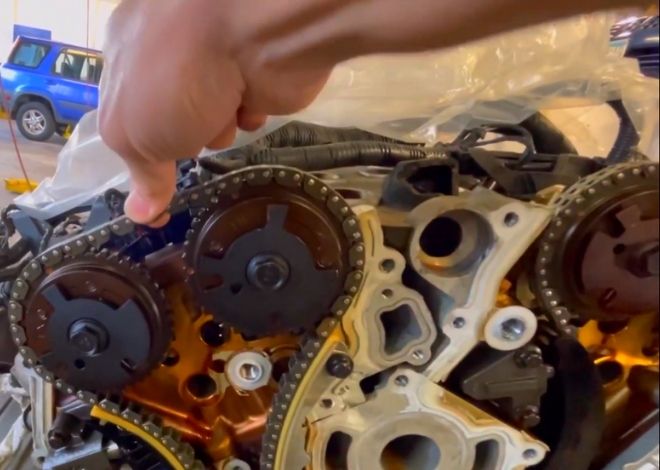

Repairing the error code P0008 is an arduous job; it needs a long time and patience to crack the code P0008. First, if all, attach the professional OBD-II scan tool to reassure the code exists. Check for any other code to see whether solving the other code solves the P0008 code automatically. Then analyze the ECM values to readdress the code. Then it is wise to check the wiring, noises, and fuel pressure. Based on the model, the top timing cover or the valve cover needs to be removed at the very beginning. To verify the actual position of the crankshaft and camshaft, rotate them from 0 degrees to 360 degrees. Verify the position according to the rotation graph. If the graph summarizes the value, there is no fault in the crankshaft and camshaft sections.

The next one you need to check is the reluctor ring; if it doesn’t align with the particular shafts, then make sure that they are in the exact position as the service manual depicts. A stretched timing belt or timing chain can cause tension and create a misalignment problem. The tooth of the timing chain may be broken or maybe dislocated, so now your duty is to fix that tooth. If a worn tensioner is misleading the rotation, replace it without any further delay. The wiring and sensor signals may detect and analyze from a digital voltage scope. The mechanic may verify the timing marks on the crank and camshaft sprocket’s alignment. After analyzing all the issues related to the crankshaft and camshaft, fix, replace and renew the faulty components.

Common Diagnosis Mistakes Of P0008 Code

The common mistake in the diagnosis of fault code P0008 is the lack of a proper OBD-II scanning tool. Sometimes inexperienced mechanics mismeasure the fault code or can not locate the exact location where the fault has occurred. Many of them can not retrieve the actual meaning of the fault code. Some mechanics intentionally claim a considerable amount of money for a very tiny problem encountered in just a few hours. That’s why the owners need to acknowledge the fault codes, as when they occur, you can fix that by yourself.

Sometimes the error code appears due to the jam in the oil pump section; the passageway may be clogged, causing the crankshaft to send error codes to the MIL. I have a significant suggestion for you: initially diagnose the code carefully and determine the actual fault in the system. Sometimes a minor flaw can cost you hundreds of Dollars.

What is the Estimated Cost of Repair?

Solving the error code P0008 is mostly a herculean task. It may require more than one repair of the parts, and each of the costs of the repairing work is individually. The costing includes labor wage and the cost of the relevant details. The repairing of the timing chain requires $600 to $1200, and to fix the Reluctor ring, you need to invest between $200 to $600. Keep in mind that the repairing cost range may vary due to some hidden factors and vocational diversity.

Conclusion

Facing the error code P0008 can be proven an extensive problem, and The code is crucial for the engine’s performance and smoothness, and perfect engine timing between the camshafts and crankshaft is considered a potential positive side for the car. If you face this problem, simply follow the guidelines to mitigate the inconvenience from your vehicle.

Kevin Nicholas is an automotive technician who is a genius at software and hardware-related issues. He manually tested more than a hundred OBD scanners and gave his honest opinion on whether the device was worth the money or not. His in-depth OBD review articles help people choose the right product, whether it is a European, American, or Asian vehicle. He completed his Automotive Specialized Training Course at Universal Technical Institute and has more than 15 years of experience in the field.

Summary of Contents