Last Updated on April 22, 2025

When your vehicle’s check engine light comes on and the diagnostic tool returns a P0341 code, it’s a clear signal that your engine may be experiencing camshaft sensor issues. This trouble code is one of many generic powertrain diagnostic trouble codes (DTCs), but its implications can be serious if not addressed in time.

P0341 – Camshaft Position Sensor “A” Circuit Range/Performance (Bank 1)

This code typically relates to the intake camshaft on a straight overhead camshaft engine and is triggered when the signal from the camshaft position sensor (CMP) does not match the expected range or timing from the crankshaft position sensor (CKP). Modern vehicles rely on precise coordination between these sensors to optimize ignition and fuel injection timing. If the ECM (Engine Control Module) detects inconsistency in the camshaft signal, it flags the P0341 error.

What Is the Camshaft Position Sensor and How Does It Work?

The camshaft position sensor (CMP) plays a crucial role in monitoring the position and speed of the camshaft. It helps the ECM determine which cylinder is on the compression stroke so it can deliver fuel and spark at the precise time.

There are two main types of CMP sensors:

- Hall Effect Sensors: These sensors have three wires—power, ground, and signal. They use a magnetic field to detect changes in position.

- Magnetic Pick-up Sensors: These usually have two wires and generate an AC signal based on movement past a reluctor wheel.

In both cases, the CMP sensor reads notches or teeth on a reluctor wheel that spins with the camshaft. As the engine runs, the sensor generates a signal that the ECM uses to time ignition and fuel injection accurately. If that signal is out of sync, inconsistent, or missing, the ECM will set a P0341 code.

What Causes the P0341 Code?

Understanding the root causes of the P0341 Camshaft Position Sensor “A” Circuit Range/Performance (Bank 1) code is essential for a successful diagnosis and repair. This error generally stems from issues that disrupt the accurate detection of the camshaft’s position, timing, or performance. Here are the detailed causes:

Faulty Camshaft Position Sensor

This is the most common cause. Over time, the sensor can fail due to wear, heat exposure, oil contamination, or internal electrical faults. A degraded sensor may produce weak or erratic signals, confusing the ECM and triggering the P0341 code.

Worn or Misaligned Timing Belt/Chain

If the timing belt or chain stretches, jumps a tooth, or becomes misaligned, it can throw off synchronization between the camshaft and crankshaft. This mismatch in timing leads to signal irregularities that can activate the P0341 code.

Damaged Reluctor Wheel

The reluctor (or tone) wheel is mounted to the camshaft and contains evenly spaced notches or teeth that the sensor reads. If this wheel becomes bent, damaged, or loose, the signal becomes distorted, resulting in faulty camshaft readings.

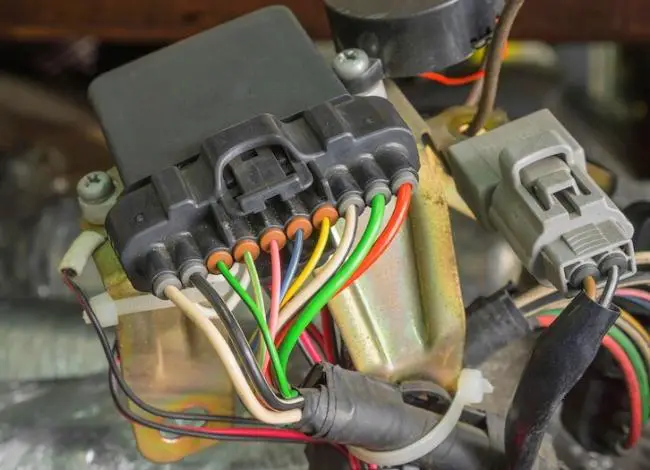

Electrical Issues (Wiring and Connectors)

Cracked insulation, corroded pins, frayed wires, or loose connections in the sensor wiring harness can cause resistance or open/short circuits. These electrical problems interfere with signal transmission from the sensor to the ECM.

Poor Ground Connection

A weak or dirty ground connection can cause signal voltage drops or noise interference. The sensor’s output may be unstable or weak, causing the ECM to interpret it as out-of-range.

Interference from Ignition Wires

If the camshaft sensor wiring is routed too closely to spark plug wires or ignition coils, electrical interference can corrupt the sensor’s signal, leading to erratic readings and false triggering of the DTC P0341.

Defective Starter Motor or Low Battery Voltage

A slow cranking engine due to a faulty starter motor or weak battery can produce inconsistent sensor signals during startup, especially if the engine cannot maintain the required RPM for proper signal detection.

Malfunctioning Powertrain Control Module (PCM)

Although rare, internal PCM failures or outdated software can lead to incorrect interpretation of sensor signals or inability to process signal range correctly, resulting in the error code.

Common Symptoms of P0341 Code

Recognizing the symptoms can help you act early and prevent further engine damage:

- Check Engine Light On: The CEL is the most obvious sign. It may be steady or flashing depending on severity.

- Hard Starting or No Start: If the CMP sensor isn’t working, the engine may crank longer or not start at all.

- Rough Idling or Stalling: The timing may be off, causing unstable RPMs.

- Poor Acceleration: The engine lacks power, especially during acceleration.

- Engine Misfires: Erratic signals can disrupt ignition timing.

- Reduced Fuel Efficiency: Incorrect timing leads to poor combustion, increasing fuel consumption.

Is the P0341 Code Serious?

Yes, P0341 is a serious issue, especially if left unattended. The camshaft and crankshaft must stay in perfect sync to ensure smooth engine operation. Misalignment can cause:

- Misfires or complete stalling

- Permanent engine damage

- Failed emissions tests

- Trouble restarting the engine

While you may be able to drive short distances, it is not advisable to ignore this issue.

How to Diagnose and Fix the P0341 Code

Properly diagnosing and fixing the P0341 trouble code involves a combination of visual inspection, electrical testing, timing verification, and occasionally component replacement. Here is a step-by-step guide broken down for ease of troubleshooting:

Step 1: Start with a Thorough Visual Inspection

Begin by examining the camshaft position sensor and its related wiring.

- Check for Obvious Damage: Look for broken wires, exposed insulation, oil contamination, or melted plastic.

- Inspect the Connector: Ensure it is clean, corrosion-free, and properly seated.

- Reroute Wires: Keep sensor wiring away from high-voltage components like spark plug wires and ignition coils to reduce interference.

Pro Tip: Wiggle the wires gently while the engine is running. If the RPM fluctuates, you likely have a wiring issue.

Step 2: Test the Camshaft Position Sensor

You’ll need a Digital Volt-Ohm Meter (DVOM) or oscilloscope.

- For Hall Effect Sensors: Check for 5V reference signal and ground at the connector. With the engine cranking, you should see a pulsing voltage on the signal wire.

- For Magnetic Pick-Up Sensors: Set your DVOM to AC voltage. You should see a small alternating voltage (millivolts to 1V) when cranking.

Note: No voltage or a flat signal indicates a faulty sensor or circuit.

Step 3: Retrieve Freeze Frame Data

Use a professional-grade OBD-II scanner to view freeze frame data. This will show the exact engine conditions when the P0341 code was set—such as RPM, coolant temp, throttle position, etc.—and help you narrow down if the issue occurred during cranking, idle, or acceleration.

Step 4: Inspect the Reluctor Wheel

If the camshaft sensor and wiring check out, the issue may be mechanical.

- Access the Reluctor Wheel: This may involve removing the timing cover or valve cover.

- Check for Damage or Misalignment: The wheel should be securely mounted and free of chips, cracks, or missing teeth.

- Verify Sensor Gap: Ensure that the air gap between the sensor and the reluctor wheel matches manufacturer specifications.

Step 5: Examine the Timing Components

A misaligned camshaft due to timing chain or belt issues can confuse the sensor.

- Verify Cam-Crank Correlation: Rotate the engine to Top Dead Center (TDC) and inspect timing marks.

- Check for Belt or Chain Slack: If you find play or signs of wear, it’s time to replace the timing components.

- Inspect Tensioner: A failed tensioner can cause chain slap, leading to intermittent sensor readings.

Step 6: Scan and Clear Codes, Then Retest

After performing repairs, clear the codes using an OBD2 scanner.

- Test Drive: Drive the vehicle through different conditions (idle, acceleration, highway) to ensure the code does not return.

- Re-scan the System: If the code reappears, continue with further diagnosis.

Step 7: Reprogram or Replace PCM (If Necessary)

If all mechanical and electrical components are functional and the issue persists, the fault may lie in the PCM.

- Check for TSBs (Technical Service Bulletins): Manufacturers sometimes release software updates to address false P0341 codes.

- Reprogram the PCM: Many shops or dealers offer reprogramming services.

- Replace the PCM: Only consider this if you’ve ruled out all other issues and verified that the ECM is corrupted.

Advanced Diagnostic Tools

Here are some advanced techniques used by professionals:

- Freeze Frame Data: Helps pinpoint conditions at the time the code was set.

- DVOM (Digital Volt-Ohm Meter): Measures voltage changes in real time.

- OBD-II Scanners: Read and clear codes, view live data, and perform system tests.

Preventive Tips for Avoiding P0341 Code

- Regular Maintenance: Replace timing belts and chains at the recommended intervals.

- Use OEM Sensors: Avoid cheap aftermarket sensors that may provide inaccurate readings.

- Avoid Electrical Interference: Keep signal wires away from high-voltage ignition components.

- Clean Connectors: Use contact cleaner to remove corrosion.

Related Trouble Codes

P0341 often appears with or is linked to other error codes. It’s useful to know them:

- P0016 – Crankshaft Position-Camshaft Position Correlation Bank 1 Sensor A

- P0017 – Crankshaft Position-Camshaft Position Correlation Bank 1 Sensor B

- P0365 – Camshaft Position Sensor “B” Circuit Bank 1

- P0335 – Crankshaft Position Sensor “A” Circuit

If you’re also seeing a P0017 Code, check out this detailed P0017 Code guide for more insights.

Summary of Fixes

| Issue | Fix |

|---|---|

| Faulty CMP Sensor | Replace the sensor |

| Damaged Wiring | Repair or replace wires/connectors |

| Worn Timing Belt/Chain | Replace timing components |

| Corroded Connectors | Clean or replace |

| ECM/PCM Error | Reflash or replace PCM |

| Reluctor Wheel Damage | Replace or realign reluctor wheel |

Final Thoughts

The P0341 error code is not something to ignore. While the vehicle may continue to run for a short period, performance will suffer and long-term damage can result. Diagnosing this code involves a mix of visual inspection, sensor testing, and occasionally deeper internal component examination. Whether it’s a faulty sensor or timing misalignment, fixing it promptly restores engine performance and reliability.

More Powertrain-Related Codes

Interested in learning more? Check out our guides on:

Kevin Nicholas is an automotive technician who is a genius at software and hardware-related issues. He manually tested more than a hundred OBD scanners and gave his honest opinion on whether the device was worth the money or not. His in-depth OBD review articles help people choose the right product, whether it is a European, American, or Asian vehicle. He completed his Automotive Specialized Training Course at Universal Technical Institute and has more than 15 years of experience in the field.