Last Updated on April 28, 2025

When you work in a corporate environment or commute daily, having a reliable car is essential. But things can quickly become frustrating if your vehicle faces unexpected issues. Vehicle problems can arise from accidents, uncontrolled driving, poor maintenance, or natural wear and tear. Among the technical faults, the C1226 code is a common error that deserves immediate attention. This code specifically indicates an issue with your vehicle’s right front excessive wheel speed (while the left front wheel issue shows as C1232 code).

Understanding this code, its causes, symptoms, and solutions can help you address the problem quickly and extend your car’s lifespan.

In this article, we will cover everything you need to know about the C1226 code in a detailed, easy-to-understand, and SEO-optimized way.

Quick Overview: Common Reasons and Solutions for C1226 Code

| Reasons | Solutions |

|---|---|

| Faulty Wheel Speed Sensor | Inspect for damage or corrosion. Replace if faulty. Ensure secure connections. |

| Broken or Damaged Wiring | Inspect the wiring harness. Repair or replace broken wires. Check for secure and clean connections. |

| Dirty ABS Ring | Clean dirt and debris from the ABS ring. Replace if corroded or damaged. |

| Faulty ABS Module | Run a diagnostic test. Replace the module if faulty. |

| Faulty ABS Pump | Inspect the pump for damage. Replace if necessary. |

| Incorrectly Installed Brake Parts | Inspect pads, rotors, and calipers. Replace or reinstall correctly. |

What Does the C1226 Trouble Code Mean?

The C1226 trouble code refers to a fault associated with the right front wheel’s speed sensor or related components. Your vehicle’s wheels must rotate evenly to ensure smooth driving and reliable braking. When one wheel, particularly the right front, fails to operate properly, your car’s braking system can be compromised.

The Electronic Brake Control Module (EBCM) continuously monitors wheel speeds via the wheel speed sensors. It measures the AC signal frequency generated by each sensor to determine wheel speed. If the right front sensor sends inaccurate signals due to malfunction, the EBCM detects the discrepancy and triggers the C1226 code.

In simple terms, if the sensor cannot correctly measure the right front wheel’s speed, the system recognizes it as a risk and alerts you by turning on the warning lights and storing the error code. Immediate attention to this issue is crucial for maintaining safe driving performance.

Possible Causes of the C1226 Code

Let’s dive deeper into all possible causes, each expanded to around 150 words.

Problematic Hub Assembly

A well-functioning hub assembly is vital for maintaining solid electrical connections between your car’s wheels and braking system. The hub contains critical components, including the wheel speed sensor, bearings, and electrical connections. When the hub assembly gets damaged due to corrosion, impact, or wear, the wheel speed sensor may lose its proper connection.

A compromised hub assembly directly affects the wheel’s movement and braking efficiency. Furthermore, a damaged assembly can generate inaccurate speed readings, confusing the ABS system and triggering error codes like C1226.

In many cases, even a minor misalignment inside the hub assembly can cause sensor failure. To prevent these issues, regular inspection of the hub and wheel bearings is essential, especially if you hear grinding noises or experience unstable steering. Replacing a damaged hub assembly on time will protect your vehicle’s stability and eliminate the chances of recurring ABS-related codes.

Defective Right Front Wheel Speed Sensor

The right front wheel speed sensor plays a critical role in monitoring wheel rotation and ensuring effective ABS (Anti-lock Braking System) operations. If the sensor becomes defective due to dirt buildup, moisture exposure, or internal failure, it will produce inaccurate speed signals.

When the ABS module detects discrepancies between expected and actual wheel speeds, it triggers the C1226 error code to warn the driver. A malfunctioning wheel speed sensor can also cause braking inconsistencies, especially during emergency stops or slippery road conditions.

Physical inspection often reveals whether the sensor is cracked, corroded, or covered in debris. Using a multimeter, you can also test the sensor’s electrical resistance. Immediate replacement of a faulty sensor is crucial to restore ABS functionality and prevent additional stress on your braking system. Addressing this sensor problem early on can also prevent more costly repairs to related ABS components.

Poor Electrical Connection

A poor electrical connection between the wheel speed sensor and the ABS module can easily trigger the C1226 code. This fault typically arises from loose connectors, corroded pins, or worn-out wiring near the sensor.

When the electrical signals between the sensor and control module are weak or intermittent, the ABS module interprets the inconsistent signals as a sensor failure. Consequently, your ABS light or check engine light will turn on, and the scanner will read a C1226 trouble code.

In most cases, fixing the issue involves inspecting and cleaning all connectors, tightening loose connections, or replacing corroded pins. It’s crucial to ensure a waterproof seal around sensor connections to prevent future issues caused by moisture infiltration. Investing a little time in electrical maintenance can save you from much bigger—and more expensive—braking system failures down the road.

Open or Shorted Harness

An open or shorted harness can severely impact the functionality of the wheel speed sensor, leading to a C1226 trouble code. The harness is responsible for transmitting electrical signals between the sensor and the Electronic Brake Control Module (EBCM).

Over time, the harness can wear out due to constant wheel movement, exposure to road debris, moisture, or improper repairs. A broken, frayed, or internally corroded harness can disrupt signal transmission, resulting in inconsistent or no readings at all.

Inspecting the harness involves checking for visible cuts, burn marks, or exposed wires. Using a multimeter to check for continuity in the harness can confirm if the circuit is broken or shorted. If any fault is found, repairing or replacing the harness is necessary. A properly functioning harness ensures the sensor communicates accurately with the ABS module, restoring the braking system’s reliability and eliminating the C1226 code.

Possible Symptoms of the C1226 Code

Let’s now expand the symptoms section point-by-point.

ABS Light On

ABS Light On

One of the most immediate and visible signs of a C1226 code is the ABS light turning on. The Anti-lock Braking System (ABS) light serves as a warning indicator whenever the system detects irregularities, especially related to wheel speed sensors.

When the right front wheel sensor or its components malfunction, the EBCM logs the C1226 fault and alerts the driver through the dashboard ABS light. While the car remains drivable in many cases, the braking performance may be compromised, especially under hard braking or slippery conditions.

Ignoring the ABS warning light is dangerous, as it means your vehicle may lose traction and stability during emergency stops. To diagnose accurately, connect an OBD-II scanner to retrieve the error codes. Prompt action upon seeing the ABS light can prevent bigger problems and keep your braking system reliable and effective at all times.

Check Engine Light On

Check Engine Light On

Although the Check Engine Light is primarily associated with engine performance, it can also illuminate due to chassis and braking system issues, including those causing the C1226 code.

When the vehicle’s computer detects discrepancies in the wheel speed sensor readings, it often triggers both the ABS light and the check engine light. This is because the wheel speed information is critical for overall vehicle dynamics and stability control systems, not just braking.

A lit check engine light combined with a noticeable change in braking behavior strongly suggests underlying problems that require urgent diagnosis. It’s advisable to avoid heavy braking or high-speed driving once the light appears. Using an OBD-II scanner helps pinpoint the exact fault code—C1226 in this case—and helps you proceed with necessary repairs. Early intervention ensures the issue doesn’t cascade into other interconnected systems like traction control or electronic stability programs.

How Much Does It Cost to Diagnose the C1226 Code?

The cost to diagnose the C1226 code can vary depending on several factors such as the vehicle model, your location, and the expertise of the repair shop. On average, most repair shops charge between $70 to $150 per hour for diagnostics. Some dealerships may charge even more due to higher labor rates.

A basic diagnostic session usually takes about one hour. During this time, technicians will use a professional-grade OBD-II scanner to pull the error codes, perform visual inspections, and possibly test the wheel speed sensor and harness. If additional tests are needed, such as oscilloscope readings or full ABS module diagnostics, the cost might increase.

Mobile mechanics may offer slightly cheaper diagnostic rates, but it’s important to choose someone experienced with ABS systems. Investing in a proper diagnosis upfront ensures you don’t waste money on unnecessary repairs, and it shortens the time your vehicle stays off the road.

Is Speed Variation Harmful for Your Vehicle?

Yes, speed variation among wheels can be extremely harmful to your vehicle and your safety.

When all four wheels spin at different speeds, your braking performance, traction, and stability are compromised. The Anti-lock Braking System (ABS) and Electronic Stability Control (ESC) rely heavily on consistent wheel speed data to prevent skidding and loss of control.

If a wheel, such as the right front, spins slower or faster than the others due to a defective sensor or mechanical issue, the braking force gets unevenly distributed. This can cause the vehicle to pull to one side during braking or fail to stop within a safe distance.

Moreover, unaddressed speed variations can trigger further mechanical wear on your braking components, suspension, and tires. Over time, it increases the risk of accidents, especially in emergency braking situations or on slippery roads.

Promptly addressing the C1226 error and maintaining wheel speed balance is crucial for overall vehicle performance and safety.

Diagnosing and Fixing the C1226 OBD Code

Here, we explain the step-by-step solutions.

Step 1: Visual Inspection

The first and simplest step in diagnosing a C1226 code is a visual inspection of the affected area. Begin by locating the right front wheel and examining the wheel speed sensor and its surrounding components.

Check the sensor for obvious physical damage, such as cracks, missing parts, or corrosion. Next, inspect the wiring harness for signs of wear, exposed wires, or loose connectors. Also, look at the ABS ring attached to the hub or axle for dirt buildup, cracks, or missing teeth.

Sometimes, the problem is simply caused by debris blocking the sensor’s ability to read properly. Cleaning the sensor area with compressed air or an appropriate cleaner can sometimes resolve the issue without needing expensive repairs.

Completing a thorough visual inspection saves both time and money by allowing you to catch and fix minor problems before moving on to more complex diagnostics.

Step 2: Test the Wheel Speed Sensor

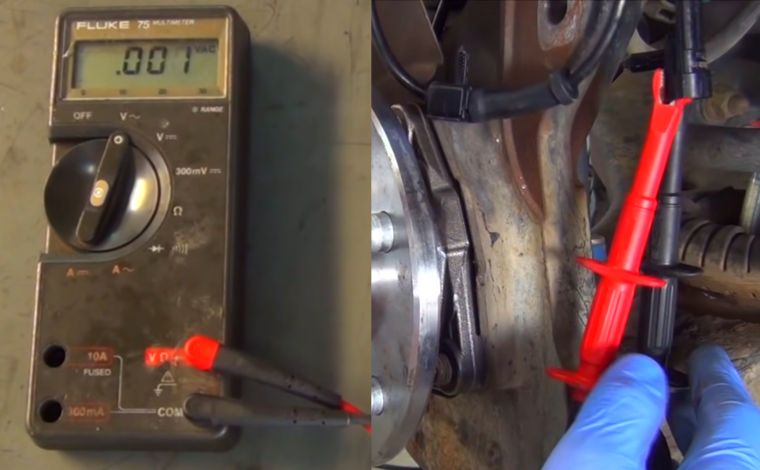

After visual inspection, the next step in diagnosing a C1226 code is to test the wheel speed sensor. This ensures the sensor is functioning correctly.

Use a digital multimeter to check the resistance across the sensor terminals. Refer to your vehicle’s service manual for the correct resistance range, as it can vary by make and model. Typically, a good sensor will show a resistance between 900 to 1300 ohms.

If the reading is significantly outside this range—either infinite (open circuit) or extremely low (short circuit)—the sensor is defective and needs replacement. Additionally, you can use an oscilloscope to view the sensor’s output waveform while spinning the wheel manually. A good sensor will produce a consistent sine wave pattern.

Testing ensures you don’t replace parts unnecessarily, making your repair both accurate and cost-effective. Replacing a perfectly good sensor due to misdiagnosis could lead to unnecessary expenses without solving the actual issue.

Step 3: Inspect the ABS Ring

An often-overlooked cause of the C1226 code is a dirty or damaged ABS ring. The ABS ring, sometimes called a tone ring, provides a reference signal for the wheel speed sensor to monitor rotation.

Over time, dirt, debris, rust, or physical damage to the ABS ring can obstruct accurate readings. A cracked or missing tooth in the ring disrupts the sensor’s magnetic field detection, causing the EBCM to interpret it as a fault, thus triggering the C1226 code.

To inspect, you may need to remove the wheel and possibly the brake rotor to access the ABS ring. If the ring is simply dirty, a thorough cleaning with brake cleaner may solve the issue. If the ring is cracked or damaged, it must be replaced to restore accurate sensor readings and ensure proper ABS function.

Skipping this step risks an incomplete repair and continued ABS system malfunction.

Step 4: Scan the System for Additional Codes

Sometimes, a C1226 code doesn’t appear in isolation. It might be accompanied by other ABS-related fault codes indicating broader system issues.

Using a professional-grade OBD-II scanner capable of reading ABS codes is crucial. Scan for any additional trouble codes related to other wheels, communication issues, or sensor malfunctions. Codes like C1221 (left front wheel), C1233 (right rear wheel), or communication failure codes can hint at deeper issues within the ABS module or the vehicle’s CAN bus network.

Identifying and addressing all related codes ensures a comprehensive repair instead of fixing one symptom and leaving others unresolved. Skipping this step could lead to the ABS light turning back on shortly after repairs, forcing you to repeat diagnostics and repairs.

A complete diagnostic session provides confidence that once repairs are completed, the vehicle will be fully restored to optimal working condition without underlying hidden faults.

Step 5: Replace the Faulty Wheel Speed Sensor

If testing confirms that the right front wheel speed sensor is faulty, replacement is the next logical step.

To replace it, safely lift the car with a jack and secure it on stands. Remove the right front wheel to access the sensor. Depending on your vehicle, the sensor may be attached to the hub assembly or mounted separately. Remove any bolts securing the sensor and carefully disconnect the wiring harness.

Install the new sensor by connecting it to the harness and securing it firmly to the mounting point. Make sure the new sensor is properly aligned and positioned close to the ABS ring for accurate readings.

After installation, clear the C1226 error code using a scanner and test-drive the vehicle to ensure the ABS light stays off. Replacing the faulty sensor ensures the braking system receives accurate wheel speed data, restoring your vehicle’s full safety features.

Step 6: Repair or Replace Damaged Wiring

If diagnostics reveal that the wiring harness is the problem, you must either repair or replace it.

Start by identifying the exact point of damage — look for cuts, burns, corrosion, or pinched sections. Minor damage like small cuts can often be repaired using heat-shrink tubing and soldering. For more severe damage, it’s safer to replace the entire section of the harness.

While repairing, ensure strong and weatherproof connections to prevent future failures. Always route the repaired wires properly to avoid exposure to moving parts like suspension or wheels.

After repairs, reconnect everything securely and scan the system again to clear the C1226 code. Test-drive the vehicle to verify that the ABS light no longer illuminates.

Properly repairing the harness restores smooth communication between the wheel speed sensor and the ABS module, ensuring the stability and reliability of your braking system.

Step 7: Clean or Replace the ABS Ring

Sometimes, solving the C1226 code is as simple as cleaning the ABS ring, also called the tone ring.

Start by removing the wheel and inspecting the ring closely. If you find dirt, debris, or light corrosion, clean the ring carefully with a soft brush and brake cleaner. Avoid using anything too abrasive that could damage the delicate teeth on the ring.

However, if the ring shows cracks, missing teeth, or severe rust, replacing it is necessary. A damaged ABS ring cannot generate the correct magnetic field patterns needed for accurate speed readings, making it impossible for even a new sensor to work properly.

Replacing the ABS ring involves removing the hub or CV axle depending on its location. After installation, rescan the system to ensure the C1226 error code is cleared.

Proper ABS ring maintenance ensures optimal sensor performance and prevents future ABS or traction control system malfunctions.

Importance of Prompt Repair for C1226 Code

Ignoring the C1226 code can lead to serious consequences beyond simple inconvenience.

First, a malfunctioning wheel speed sensor or related components severely compromises the effectiveness of your ABS and traction control systems. In emergency braking situations, especially on wet, icy, or uneven roads, you may not have the stability needed to avoid an accident.

Second, continued driving with unresolved ABS issues can result in increased wear on your brakes, suspension system, and tires. Over time, the cost of neglect multiplies, making repairs more expensive.

Third, in some jurisdictions, a non-functional ABS system can cause your vehicle to fail safety inspections, making it illegal to drive until fixed.

By addressing the C1226 code promptly, you protect not only your safety but also your vehicle’s longevity and resale value. Quick action saves money, prevents accidents, and gives you peace of mind knowing that your car is ready for any road condition.

How to Prevent C1226 Code Recurrence

Preventing the recurrence of the C1226 error code involves a proactive maintenance approach.

First, schedule regular inspections of your vehicle’s wheel speed sensors, ABS rings, and wiring harnesses—especially after driving in harsh conditions like snow, mud, or gravel roads.

Second, avoid aggressive driving behaviors that can put excessive stress on your hub assemblies and sensors. Potholes, curbs, and off-road terrains can easily damage these sensitive components.

Third, ensure that any brake service or wheel bearing replacement is performed by qualified mechanics who understand the importance of proper sensor alignment and torque specifications. Improperly installed parts can damage ABS components without immediate symptoms.

Lastly, investing in periodic ABS system scans using an OBD-II tool helps detect small issues before they escalate. Catching minor faults early can save you from costly repairs and guarantee optimal performance.

Following these preventative steps will minimize your risk of facing the C1226 code again in the future.

Final Words

The turning on of the ABS light and the engine light indicates problems related to the functions of a vehicle. But, the OBD II code indicates a specific problem. Whenever you repair your car’s functional issues, you must check the OBD II code through the scanner and find out the real issue. First, checking the ‘possible causes’ is essential in choosing the most appropriate way to fix the vehicle. But, if you can not identify the reasons for the issues with the car, you will fail to determine the solution. So, checking the problem and solving this in the best way is essential to keep your vehicle used for a long time.

Meet our professional car mechanic, Russell D. Steele, who has been in this field for five consecutive years and works with several automotive companies. He completed the "AUTOMOTIVE & LIGHT DUTY DIESEL TECHNOLOGY" course from NorthWest Lowa Community College, where he learned essential diagnostic and transportation management skills and became a certified mechanic.